The ultimate outdoor makeover

Perhaps the most dramatic showcase for the Infinity range of composite decking can be found at the imposing Aberfoyle Lodge in the eastern highland tea plantations of Zimbabwe. The imposing Arches@Aberfoyle was designed by a leading Zimbabwean architect, and incorporates a suspension bridge design that also includes a viewing deck, art gallery and wedding venue.

Completed in November 2021, the ambitious span of the structure made Infinity a natural for the project. Infinity, as a composite bamboo and polymer decking material, has achieved global renown in the construction industry for its strength, light weight and durability.

“With the expansion of our company and product portfolio, we have been fortunate to have been involved with some dramatic buildings and structures all around the world,” said Marc Minne, Co-founder and CEO of Eva-Last.

The sheer ambition of the Arches@Aberfoyle structure and its idyllic natural setting perfectly echoes Eva-Last’s values of sustainability, innovation, accountability and customer excellence.

Of course, with the ever-expanding global reach of Eva-Last, there are countless projects and structures that could inspire similar associations. There are simply too many projects to mention where Infinity has been the product of choice for corporates, architects and property owners alike. After making its TV debut on a well-known Australian television show known as The Block, Infinity sales in Caribbean Coral sky rocketed, and for good reason.

The Infinity technology is Eva-Last’s most durable composite option in its ever-increasing range of bamboo-polymer composite construction products. The streaked colour patterns in the capping give a pleasing appearance that closely resembles the look of timber, and the various colour options available in Infinity mimics different wood grains to allow for diverse timber effects.

In 2017 Eva-Last saw the need for a new, lighter and more cost-effective deck board, and through innovative design, developed the I-Series board. This new board profile has proved to be immensely popular from the outset for a number of reasons. We based the I-Series board on an I-Beam profile design as it makes it incredibly strong. The profile design means that less material is used in its construction, so it is both lighter and more cost-effective to produce.

The triangulated design of the I-beam’s underside pedestals means that it is extremely strong, from a load-bearing perspective, and is able to maintain span capability despite containing less materials.

Of course, with the ever-expanding global reach of Eva-Last, there are countless projects and structures that could inspire similar associations. There are simply too many projects to mention where Infinity has been the product of choice for corporates, architects and property owners alike. After making its TV debut on a well-known Australian television show known as The Block, Infinity sales in Caribbean Coral sky rocketed, and for good reason.

The Infinity technology is Eva-Last’s most durable composite option in its ever-increasing range of bamboo-polymer composite construction products. The streaked colour patterns in the capping give a pleasing appearance that closely resembles the look of timber, and the various colour options available in Infinity mimics different wood grains to allow for diverse timber effects.

In 2017 Eva-Last saw the need for a new, lighter and more cost-effective deck board, and through innovative design, developed the I-Series board. This new board profile has proved to be immensely popular from the outset for a number of reasons. We based the I-Series board on an I-Beam profile design as it makes it incredibly strong. The profile design means that less material is used in its construction, so it is both lighter and more cost-effective to produce.

The triangulated design of the I-beam’s underside pedestals means that it is extremely strong, from a load-bearing perspective, and is able to maintain span capability despite containing less materials.

Infinity is available in various board profiles to meet the demands of various global markets or differing installation requirements. The most widely used profile is the double-sided grooved board option which is secured using Eva-Last’s HULK hidden deck fasteners for the neatest of finishes.

The Infinity range also offers a square-edged board, ideal for deck and stair edges, and can also be used as an attractive “deck-on-the-wall” cladding application. Thanks to Eva-Last’s all-inclusive approach to installation, Hulk Fasteners composite screws are produced in matching colours to complement the Infinity range and create a seamless look.

For trims, or screening as alternative applications, the Infinity double-sided fascia board is available as a lighter weight material. With a non-load bearing design, the Infinity fascia board matches Infinity decking profiles in grain and colour and is ideal for finishing deck edges.

Infinity composite technology carries a 25-year warranty across all of its products.

Eva-Last, which has its headquarters in South Africa, has been an amazing success story since its formation back in 2006. The company has a genuine commitment to environmental sustainability and it has seen a growing acceptance of its non-timber-based construction products amidst ever-growing concern over deforestation.

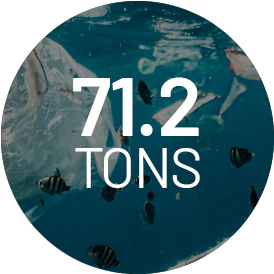

Infinity composite is produced from bamboo which is a readily available resource, with a four-year-regrowth cycle, while typical timber forests have a 20-year renewal cycle; together with the polymer component made from recycled plastics.

The Infinity range also offers a square-edged board, ideal for deck and stair edges, and can also be used as an attractive “deck-on-the-wall” cladding application. Thanks to Eva-Last’s all-inclusive approach to installation, Hulk Fasteners composite screws are produced in matching colours to complement the Infinity range and create a seamless look.

For trims, or screening as alternative applications, the Infinity double-sided fascia board is available as a lighter weight material. With a non-load bearing design, the Infinity fascia board matches Infinity decking profiles in grain and colour and is ideal for finishing deck edges.

Infinity composite technology carries a 25-year warranty across all of its products.

Eva-Last, which has its headquarters in South Africa, has been an amazing success story since its formation back in 2006. The company has a genuine commitment to environmental sustainability and it has seen a growing acceptance of its non-timber-based construction products amidst ever-growing concern over deforestation.

Infinity composite is produced from bamboo which is a readily available resource, with a four-year-regrowth cycle, while typical timber forests have a 20-year renewal cycle; together with the polymer component made from recycled plastics.

Photography Credit: Chris Scott | Copyright © Scotty Photography – All rights reserved.